Introduction to Hot Spot Detection

Hot Spot Detection with Thermal Imaging helps industries identify overheating components before they fail. Have you ever wondered why machines suddenly fail or why electrical systems burn out without warning? In most cases, the issue begins as a small, unnoticed hot spot that increases over time and causes serious damage.

At Agile Microsys Pvt. Ltd., we help industries implement advanced thermal imaging solutions to enhance safety, reduce costs, and ensure smooth operations.https://www.linkedin.com/company/agilemicrosys

What is Thermal Imaging?

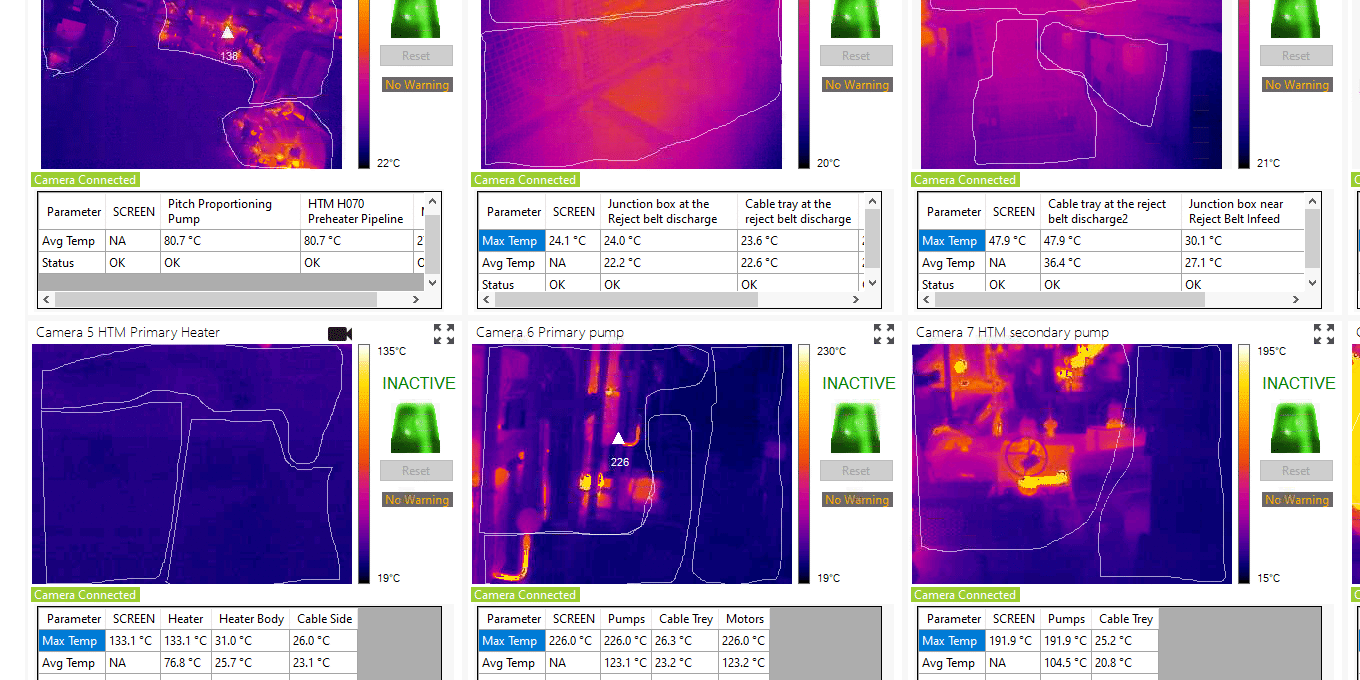

Thermal imaging works by detecting the infrared energy objects release and transforming it into a visible image. Unlike normal cameras, which rely on visible light, thermal cameras detect heat signatures, allowing us to see temperature differences even in complete darkness.

Why Industries Need Hot Spot Detection with Thermal Imaging

Hot spots might look harmless at first, but they are ticking time bombs. In electrical panels, they could spark fires. In mechanical systems, they may indicate failing bearings. For industries, early detection means fewer breakdowns, lower repair costs, and most importantly, improved safety for workers. That’s why companies like Agile Microsys Pvt. Ltd. provide innovative thermal imaging solutions to ensure business continuity and safety.

How Thermal Imaging Detects Hot Spots

Thermal imaging works on a simple principle: everything emits infrared radiation based on its temperature. A thermal camera captures this energy and displays it in different colors. Hotter areas appear brighter, while cooler ones look darker. This heat map makes it easy to spot abnormal temperature rises, pinpointing potential issues instantly.

Applications of Hot Spot Detection

Electrical Systems

Identifying loose connections in switchgear

Detecting overheating transformers

Monitoring overloaded circuit breakers

Mechanical Equipment

Locating friction in motors and bearings

Spotting misalignment in rotating machinery

Building Inspections

Detecting insulation breakdowns

Spotting hidden roof leaks

Identifying fire risks before they escalate

Energy Industry

Ensuring efficiency in solar panels

Checking wind turbine components

Inspecting high-voltage power lines safely

At Agile Microsys Pvt. Ltd., we support industries across India with cutting-edge FLIR thermal imaging technology for all these applications.https://www.flir.com/

Benefits of Hot Spot Detection with Thermal Imaging

Non-contact safety: No need to touch live wires or hot machinery.

Speed: Inspections can be completed quickly across large areas.

Accuracy: Detects even small temperature variations that human eyes would miss.

Prevention: Stops small issues from turning into catastrophic failures.

Comparing Thermal Imaging with Traditional Methods

Traditional inspections often rely on visual checks or physical touch. Both are risky and unreliable. Thermal cameras, however, provide real-time, accurate insights without downtime. Unlike contact sensors that only measure one point, thermal imaging gives a complete picture of heat distribution.

Key Features of Thermal Imaging Cameras for Hot Spot Detection

When choosing a camera, key factors include:

Resolution: Higher resolution means clearer images.

Sensitivity: Ability to detect minute temperature differences.

Temperature Range: Suitable for industrial or building inspections.

Connectivity: Some cameras allow Wi-Fi or Bluetooth for instant reporting.

Case Studies of Hot Spot Detection

A manufacturing plant avoided a major production shutdown by detecting a failing motor bearing early.

An electrical utility company prevented transformer fires by using thermal imaging inspections.

A solar farm identified defective panels, improving efficiency by 20%.

Agile Microsys Pvt. Ltd. has successfully delivered similar solutions to clients, helping them avoid major losses and improve efficiency.

Watch how we helped industries detect hot spots early in this video

Challenges in Hot Spot Detection

While thermal imaging is powerful, it does face challenges:

Environmental Factors: Sunlight, reflections, or rain can affect readings.

Cost: High-quality cameras can be expensive, though prices are dropping.

How to Choose the Right Thermal Imaging Camera

Not all industries need high-end models. For basic building inspections, entry-level cameras work fine. But for power plants or manufacturing, advanced models with higher sensitivity are crucial. At Agile Microsys Pvt. Ltd. We provide expert guidance to ensure every client chooses the right option for their specific goals.

Future of Hot Spot Detection with Thermal Imaging

The future is exciting! With AI-powered analytics, thermal cameras don’t just detect heat anomalies—they predict possible equipment failures in advance, enabling true preventive maintenance. Integration with IoT systems means remote monitoring will become the norm, enabling truly predictive maintenance.

Tips for Effective Hot Spot Detection

Schedule inspections regularly rather than waiting for breakdowns.

Train your team to analyze thermal images correctly.

For accurate trend analysis, compare current thermal scans with historical data to identify temperature variations over time.

Myths and Misconceptions About Thermal Imaging

Myth 1: Thermal cameras see through walls. (They don’t — they only detect surface heat differences.

Myth 2: They are only for large industries. (Small businesses and homeowners benefit too.

Myth 3: They are complicated to use. (Modern cameras are user-friendly and intuitive.

Conclusion

Hot spot detection with thermal imaging is no longer just an industrial luxury — it’s a necessity. Whether it’s preventing fires in electrical systems, avoiding costly breakdowns in machinery, or improving energy efficiency, thermal cameras are powerful allies in maintenance and safety.

At Agile Microsys Pvt. Ltd., we are committed to helping industries in India adopt world-class thermal imaging technology for safer, smarter, and more efficient operations.

Contact Agile Microsys Pvt. Ltd. today for expert consultation.https://agilemicrosys.com/

FAQs

- Can thermal imaging see through walls?

No, it only detects surface temperature differences, not through solid objects. - How often should hot spot inspections be done?

For vital equipment, scheduling inspections every month or quarter is strongly advised. - Is thermal imaging safe for humans?

Yes, it’s completely safe since it only measures infrared radiation emitted by objects. - What industries benefit the most from hot spot detection?

Electrical utilities, manufacturing, building inspections, and renewable energy sectors. - Can thermal imaging be used outdoors in sunlight?

Yes, but technicians must account for reflections and environmental factors when analyzing results. - What is Hot Spot Detection with Thermal Imaging?

Hot Spot Detection with Thermal Imaging is a non-contact inspection method that identifies overheating components using infrared cameras before equipment failure occurs.