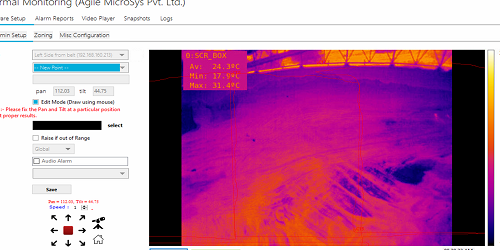

Introduction to Coal Yard Thermal Monitoring System Installation

The Coal Yard Thermal Monitoring system at Shree Cement improves plant safety. Coal storage areas can generate heat inside the pile. Therefore, temperature monitoring becomes very important. If heat increases without notice, it may cause fire or damage.

For this reason, Agile Microsys Pvt. Ltd. installed a reliable thermal camera system. As a result, the plant now receives early warnings of hot spots.

Why Coal Yard Thermal Monitoring System Installation Is Important

Coal can catch fire easily. Because of this, heat can build up inside the coal pile. In addition, conveyor belts and motors also produce heat during operation.

Therefore, manual checking is not enough. Instead, automatic thermal monitoring provides continuous protection. Moreover,it works 24/7 without stopping.

According to international fire safety guidelines from the NFPA (National Fire Protection Association), continuous monitoring reduces industrial fire risks. https://www.nfpa.org

Our Thermal Monitoring Solution

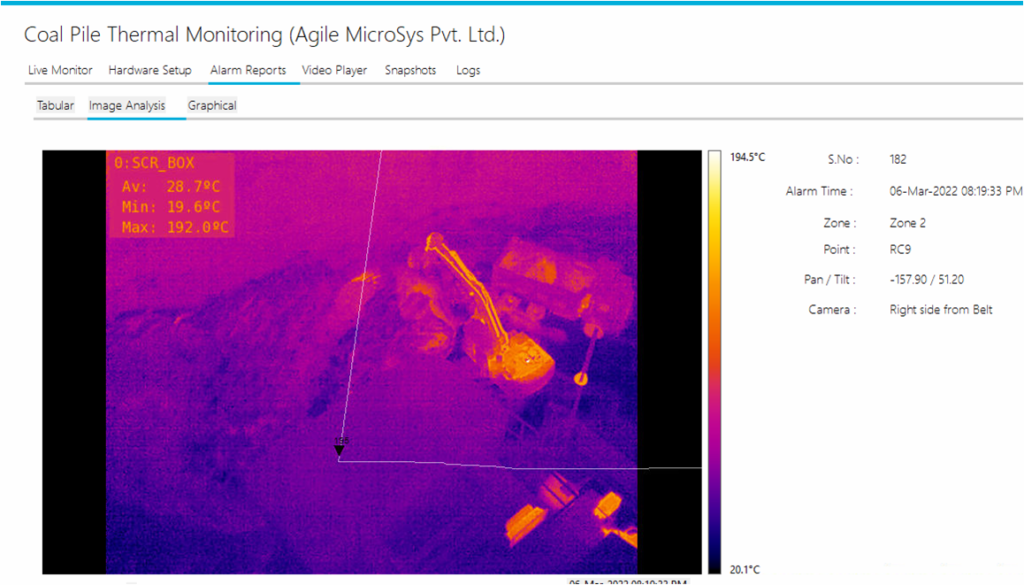

Agile Microsys Pvt. Ltd. installed advanced Thermal Imaging Cameras for 24/7 monitoring.

You can explore our complete range of Thermal Imaging Cameras

https://agilemicrosys.com/thermal-imaging-camera/

These cameras check temperature all the time in:

- Coal storage piles

- Conveyor systems

- Transfer points

- Electrical panels

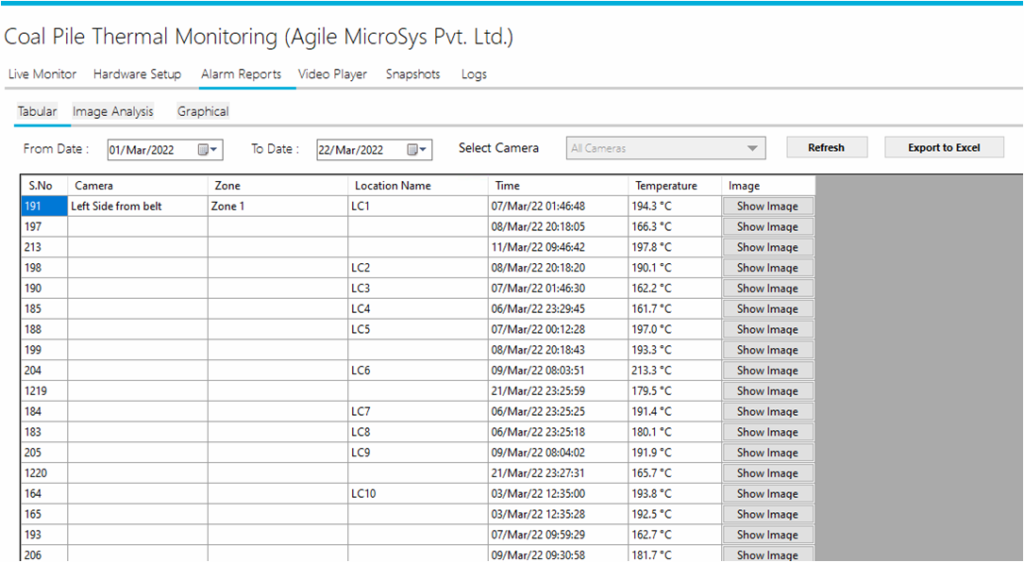

As soon as temperature goes above the set limit, the system sends an alert Consequently, the maintenance team can take immediate action.

System Features of Coal Yard Thermal Monitoring System Installation

First, the system scans the entire coal yard continuously.

Next, it measures temperature in real time.

If temperature crosses the limit, the system immediately generates an alert. As a result, the maintenance team can take quick action.

In addition, the system stores data for future analysis. Therefore, the plant can plan maintenance more effectively.

Installation Process

First, our team conducted a site survey. Then, we selected the best mounting locations. After that, we installed and calibrated the cameras. Finally, we tested the system under working conditions.

Because coal yards contain dust and high temperature, we used strong industrial cameras. Therefore, the system performs reliably in tough working conditions.

Benefits of Coal Yard Thermal Monitoring System Installation

As a result of this installation, the plant achieved several benefits.

- Reduced fire risk

- Improved safety

- Lower downtime

- Better repair planning

Moreover, early detection helps prevent major losses. Therefore, the investment provides long-term value.

Related Products Used

This project uses reliable solutions from our

FLIR Thermal Imaging Camera Series

https://agilemicrosys.com/flir-thermal-imaging-camera/

In addition, you can explore more industrial projects here:

Our Project Installations

https://agilemicrosys.com/projects/

Conclusion

In conclusion, Coal Yard Thermal Monitoring plays an important role in industrial safety. Because coal yards carry fire risk, continuous temperature monitoring becomes essential. Therefore, installing a thermal monitoring system protects assets and improves plant reliability.

Contact Agile Microsys Pvt. Ltd. today:

https://agilemicrosys.com/contact-us/