Introduction to Thermal Imaging for Electrical Maintenance

Thermal imaging for electrical maintenance is a powerful technique used to detect hidden hotspots, prevent electrical hazards, and improve maintenance efficiency in industrial and commercial systems.Electrical systems rarely fail without warning. Most failures begin quietly, hidden behind panels and inside equipment, slowly building heat until damage occurs. Thermal imaging technology makes these invisible problems visible.

At Agile Microsys Pvt. Ltd., we help industries detect electrical hotspots early using advanced thermal imaging techniques, enabling safer operations, reduced fire risk, and improved maintenance planning.

https://agilemicrosys.com/

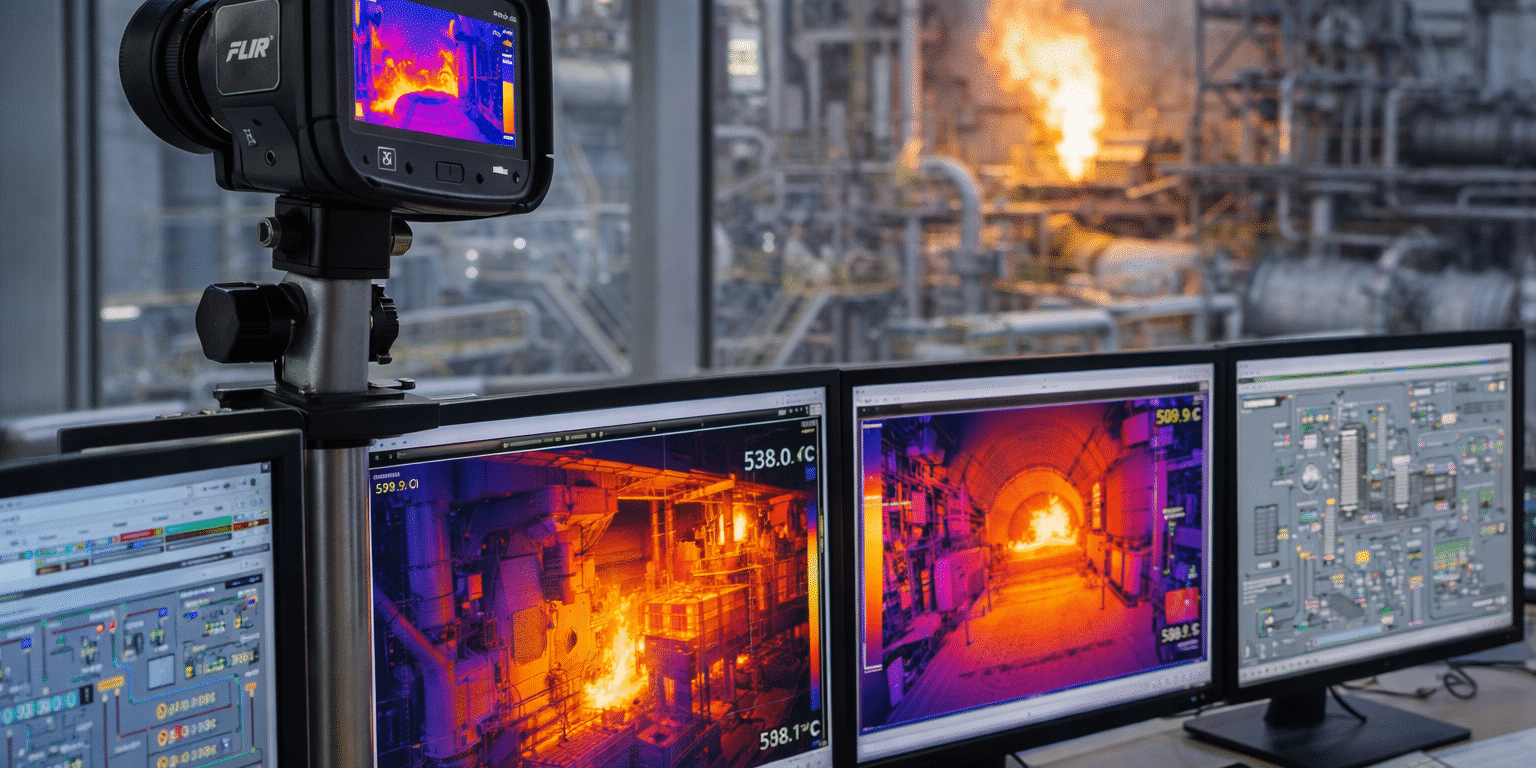

What Are Thermal Imagers in Electrical Maintenance?

Thermal imagers are devices that detect infrared radiation emitted by objects and convert it into visual heat maps. Instead of seeing light, they see temperature differences.

Infrared Radiation in Thermal Imaging for Electrical Maintenance

All electrical components generate heat when current flows. When resistance increases due to faults, heat rises abnormally. Thermal imagers capture this infrared energy and highlight it clearly.

How Thermal Cameras Convert Heat into Images

Thermal cameras translate temperature data into color-coded images called thermograms, where abnormal heat patterns stand out instantly.

Electrical Hotspots in Thermal Imaging Inspections

Hotspots are localized areas of excessive heat that indicate developing electrical faults.

Common Causes of Electrical Hotspots

- Loose connections

- Corroded terminals

- Overloaded circuits

- Phase imbalance

- Insulation degradation

Why Hotspots Are Dangerous

Hotspots can lead to:

- Electrical fires

- Arc flash incidents

- Equipment damage

- Costly downtime

Ignoring them is like ignoring a warning alarm.

The Role of Thermal Imaging for Electrical Maintenance in Hotspot Detection

Thermal imagers allow fast, safe, and accurate inspections without shutting down equipment.

Non-Contact and Real-Time Inspection

Live electrical systems can be scanned safely from a distance, reducing risk to technicians.

Accuracy and Early Fault Detection

Even small temperature deviations can be identified before failure occurs.

Thermal Imaging for Electrical Maintenance vs Traditional Inspection Methods

Limitations of Visual Inspections

Visual checks cannot detect internal heating or hidden faults inside panels.

Why Thermal Imaging Is More Reliable

Thermal imaging provides measurable data, not assumptions, making it far more effective for early fault detection.

Preventing Electrical Hazards Using Thermal Imagers

Thermal imaging plays a critical role in hazard prevention.

Reducing Fire Risk

Overheating electrical components are a major cause of industrial fires. Thermal imaging identifies these risks early.

Preventing Arc Flash and Equipment Failure

Many arc flash incidents begin with unnoticed overheating. Early detection prevents dangerous failures.

Improving Electrical Maintenance with Thermal Imaging Technology

Thermal imaging upgrades maintenance from reactive to proactive.

Predictive Maintenance Explained

Temperature trends help predict failures before breakdowns occur.

Preventive vs Reactive Maintenance

Preventive maintenance reduces repair costs, downtime, and safety risks.

Industries That Benefit from Thermal Imaging for Electrical Maintenance

Power Generation and Transmission

Thermal inspections improve reliability in substations, transformers, and switchyards.

Manufacturing and Heavy Industry

Continuous production environments rely on early fault detection to avoid shutdowns.

Commercial Buildings and Infrastructure

Hospitals, data centers, and malls use thermal imaging for safety and compliance.

How Thermal Imaging for Electrical Maintenance Supports Safety Compliance

Electrical Safety Standards

Thermal reports support safety audits and insurance requirements.

Health and Safety Risk Assessments

Thermal data strengthens documentation for risk assessments and compliance checks.

Best Practices for Thermal Imaging in Electrical Maintenance

Inspection Frequency

Critical systems should be inspected quarterly; others at least annually.

Load Conditions for Accurate Results

Inspections should be done under normal or peak load conditions.

Common Mistakes to Avoid During Thermal Inspections

- Inspecting unloaded equipment

- Ignoring baseline temperature data

- Misreading reflections as heat

- Using low-resolution imagers

Avoiding these mistakes ensures reliable results.

Choosing the Right Thermal Imager for Electrical Maintenance

Resolution and Sensitivity

Higher resolution ensures better hotspot identification.

Industrial-Grade Features

Look for temperature alarms, image storage, and professional reporting tools.

Role of Thermal Imaging for Electrical Maintenance in Fire Risk Assessment

Thermal imaging is one of the most effective tools for identifying fire hazards before ignition occurs.

Thermal Imaging and Electrical Hazard Mitigation

By addressing hotspots early, organizations significantly reduce electrical accident risks.

Cost Benefits of Using Thermal Imagers

Preventing one major failure can save far more than the cost of inspection equipment.

Future of Thermal Imaging for Electrical Maintenance

AI-based analytics, continuous monitoring, and cloud reporting are shaping the future of thermal inspections.

Why Thermal Imaging Is a Smart Long-Term Investment

With proven safety, cost, and reliability benefits, thermal imaging is a must-have for modern electrical maintenance programs—especially when implemented by experienced providers like Agile Microsys Pvt. Ltd..

Conclusion

Thermal imagers play a vital role in detecting electrical hotspots, preventing hazards, and improving maintenance efficiency. By making hidden heat visible, organizations can move from reactive repairs to proactive safety strategies. With expert support from Agile Microsys Pvt. Ltd., industries can implement thermal imaging solutions that protect people, assets, and operations.

Watch Real Thermal Inspections

To see actual thermal inspections, hotspot detection, and case studies, visit our YouTube channel :

https://www.youtube.com/@AgileMicrosys

Connect With Us on LinkedIn

Follow Agile Microsys Pvt. Ltd. on LinkedIn for industry insights, project updates, and electrical safety best practices:https://www.linkedin.com/company/agilemicrosys

About Agile Microsys Pvt. Ltd.

Agile Microsys Pvt. Ltd. is an industrial solutions provider specializing in thermal imaging inspections, electrical safety audits, and condition monitoring for power, manufacturing, and infrastructure sectors.

https://agilemicrosys.com/

FAQs

1. What does a thermal hotspot indicate?

It usually indicates high resistance, overload, or a developing electrical fault.

2. Can thermal imaging prevent electrical fires?

Yes, it identifies overheating components before ignition occurs.

3. Is thermal inspection safe on live equipment?

Yes, thermal imaging is a non-contact and safe inspection method.

4. How often should thermal inspections be performed?

Quarterly for critical assets and annually for standard systems.

5. Is thermal imaging suitable for preventive maintenance?

Absolutely. It is one of the most effective predictive maintenance tools.