-

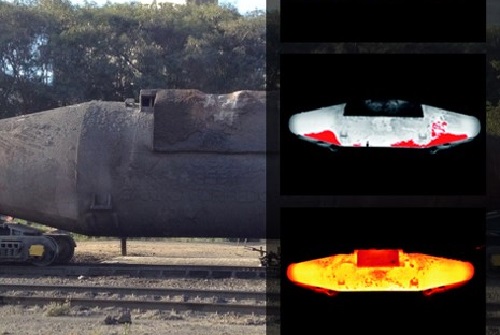

Thermal cameras installed on high masts at strategic coal yard locations

-

Pan/Tilt cameras for wide coverage with fewer units

-

Wireless connectivity to the central control room

-

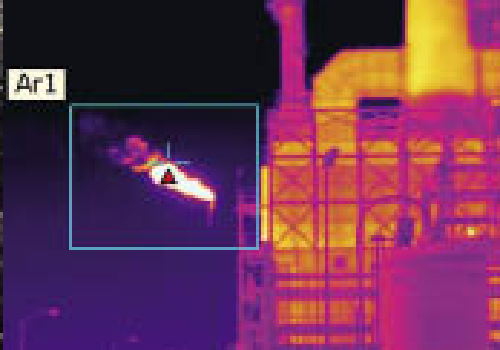

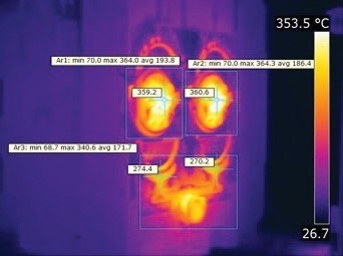

Real-time hotspot alarms with automatic logging

-

Alarm data includes temperature, time, location, and thermal image

-

Early hotspot detection to prevent self-combustion

-

Reduces coal loss, safety risks, and productivity downtime

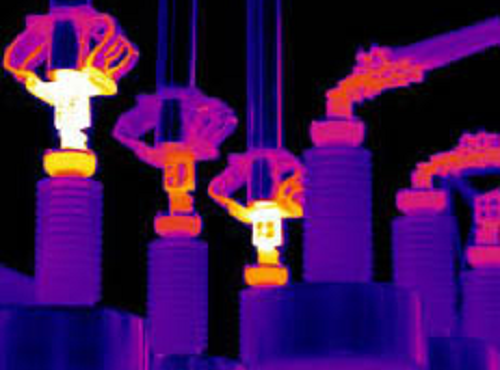

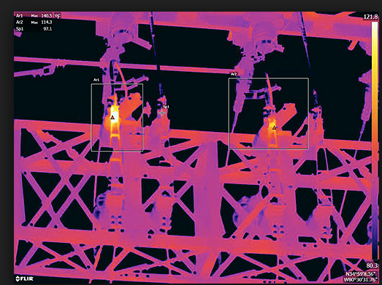

Substation Monitoring

- Thermal imaging technology can improve the reliability and security of electric substations.

- These systems employ advanced sensing and measurement technology, control methods, and digital communications.

- They are able to anticipate, detect, and respond rapidly to problems, thereby reducing maintenance costs, the chance of failure, a blackout, and lost productivity.