An electric flashover is one of the most serious and lesser understood electrical hazards. It is a continuous electric discharge that flows through an air gap between conductors which generates a very bright light as well as immense heat. Flashovers, in turn, are subjected to several factors – such as high voltages, direct or low impedance, high temperatures, etc.

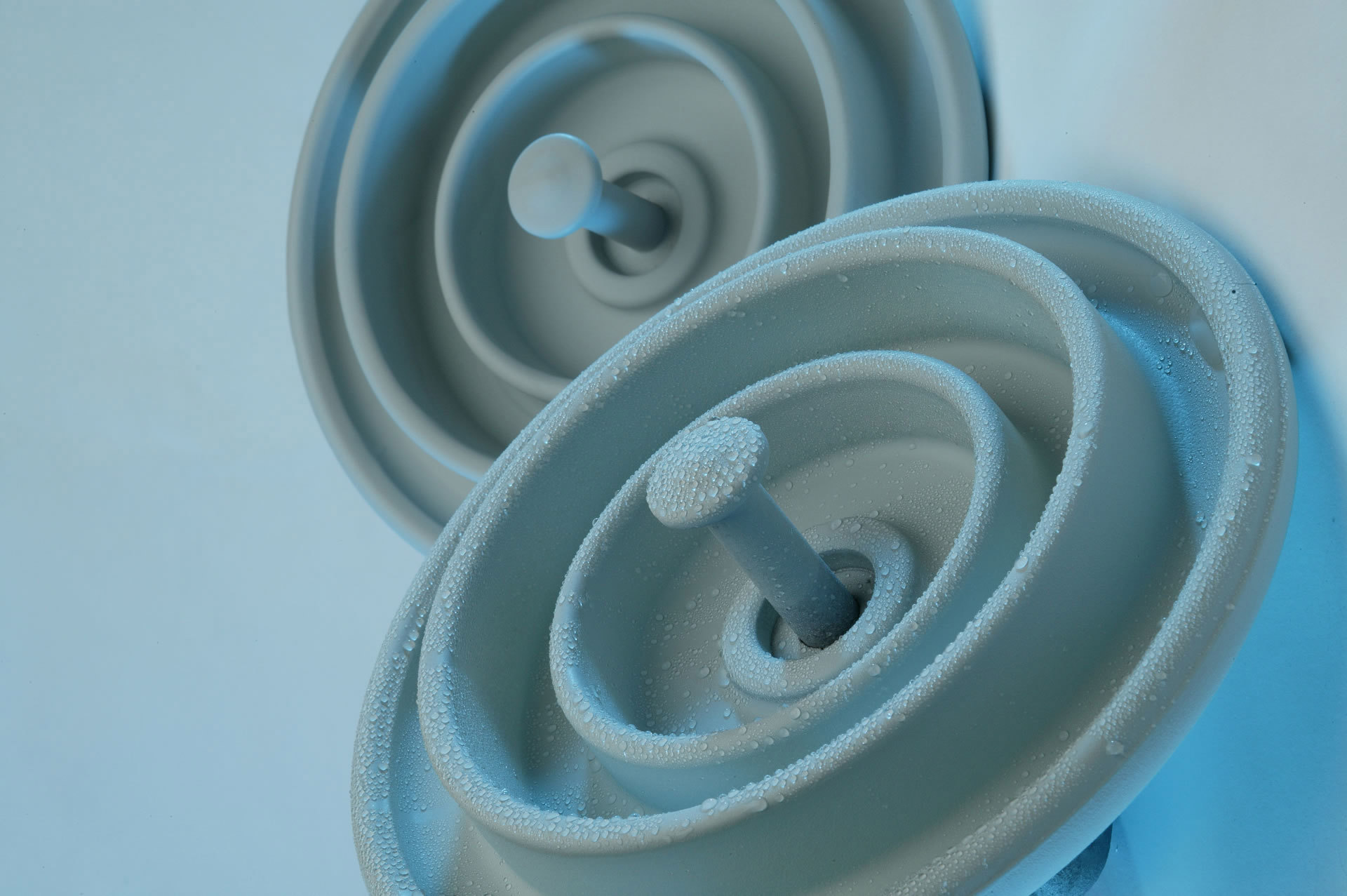

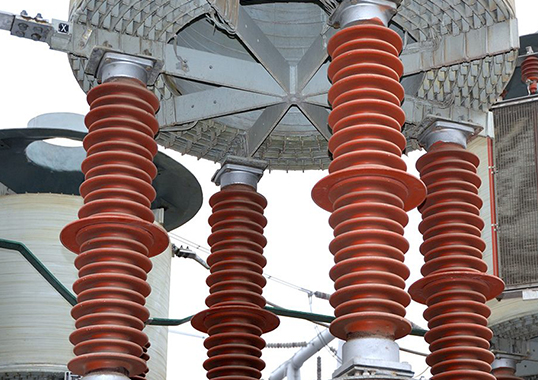

To avoid leakage currents, discharges, and pollution flashovers, a silicone layer is applied to the insulator surface by using a special spray coating technique. The silicone layer provides a hydrophobic surface that combats the negative effects of contamination and enhances the electrical characteristics of the insulator in highly polluted areas.

To avoid leakage currents, discharges, and pollution flashovers, a silicone layer is applied to the insulator surface by using a special spray coating technique. The silicone layer provides a hydrophobic surface that combats the negative effects of contamination and enhances the electrical characteristics of the insulator in highly polluted areas.

Benefits of RTV Silicone High Voltage Insulator Coating

-

MAINTENANCE COSTS – Complete elimination of washing/cleaning of Insulators even under Class IV pollution levels

-

GRID ECONOMICS – Supresses the leakage current and reduce the direct losses due to the leakage current and corona discharges

-

VERSATILE – Suitable for both new and existing insulators and can be applied on all type of Insulators (Porcelain Disc, Porcelain Long Rod, Glass Disc, Composite/Polymer)

-

LONG LASTING – The RTV Coating is unaffected by the tropical climate, extreme weather conditions, UV and all major Chemicals to offer a longest service life of more than 25 years.

-

EASY APPLICATION – The RTV Coating can be applied on in-situ conditions and there is no need for dismantling of the equipment including the gantry insulator strings

-

ENVIRONMENTALLY FRIENDLY – The Coating is a Non-Toxic and VOC Compliant

-

TECHNOLOGY & LIFE – It offers the best of both worlds, (i.e.) The Mechanical Strength of Porcelain Insulators and the Hydrophobicity of Composite (Polymer) Insulators with life of more than 25 years

How does the RTV Silicone Coating work?

-

The accumulation of contaminants on the insulator (due to industrial pollution, urban pollution and salt vapour) when combines with the water filming (due to dew, fog & light rain) results in discharges, dry band arcing and eventual flash over.

-

The RTV Silicone High Voltage Insulator Coating imparts an Ultra Hydrphobic Surface on Insulator and prevents wetting of contaminants

-

The diffusion of Low Molecular Weight Silicones (LMWS) to the surface of the insulator encapsulates the contaminants and neutralizes them throughout the service life

-

The arc resistance filler (Alumina Tri Hydrate or ATH) suppresses the heat during dry band arcing and prevents degradation of the coating.

Superior RTV Silicone Coating for High Voltage Insulators – Maximum Performance and Protection

Are you seeking a reliable solution to safeguard your high-voltage insulators from harsh weather? Agile MicroSys specializes in creating protection. It presents an RTV Silicone Coating that prevents insulators from getting dusty and from being affected by moisture or any other pollutant in the environment. RTV (Room Temperature Vulcanizing) silicone offers a long-lasting protective thermal insulation coating that is highly durable and reliable for high-voltage equipment under various conditions.

What is RTV Silicone and Why Choose It?

RTV Silicone is a high-temperature silicone that cures at room temperature. It is also known as room-temperature vulcanizing silicone. It forms an elastic but hard layer on insulators. This premium siliconized paint from Agile MicroSys offers:

- High resistance to acts of weathering and ultraviolet light exposure

- High-quality thermal insulation for high-temperature areas

- Durable, long-lasting safety that will need less maintenance.

Key Benefits of Our High Voltage Insulator Coating

Choosing our RTV coating for insulators means you benefit from:

- Improved resistance to intense weather situations

- Thermal insulation coating benefits, preventing heat exchange

- Low maintenance requirements which in turn saves time and money

- Shielding from corrosives and toxic implications of the environment

High Temperature RTV – Reliable Under Extreme Conditions

Our high-temperature RTV coatings are designed for high-demanding conditions. Unlike normal coating systems, this silicone coating delivers unmatched resilience against thermal and environmental stress. Thus it is a perfect choice for high-voltage and industrial applications.

Expert Coating Services Tailored for Performance

Learning from our many years of experience in this profession, we, at Agile MicroSys, pay care in every coating service we offer. Embedded in RTV silicone rubber coatings, our experienced team carefully lays down a durable sealant that protects structures from moisture, dust, and other degrading factors. This precision application shields insulators and also affirms long-term quality performance.

How Our RTV Silicone Coating Works

Our RTV silicone compresses the insulators and forms a layer that prevents accumulation and intrusion of contaminants. Our solution accumulates on high-voltage insulators thus keeping them clean, lowering their maintenance frequency, and increasing their performance.

Why Choose Agile MicroSys for High Voltage Insulator Coatings?

Choose us for these reasons:

- Custom Solutions: The RTV silicone coatings that we offer have been specially designed and compounded to suit the specific needs of every single client, hence the suitability and durability of the coatings on high-voltage insulators.

- Proven Quality: We check our high-temperature silicone products rigorously for their compatibility to withstand severe climates, harsh weather, and potential working situations. Thus we ensure the products’ insulation and durability profile.

- Dedicated Support: Our Agile MicroSys has a full-service team, to identify your perfect product, and assist you in its suitable application. We aim to provide friendly advice and professional solutions for all your insulation requirements.

Rely Us To Get The Optimum Results

To meet the demands of high voltage insulator coating Agile MicroSys presents the RTV Silicone with top-notch quality and reliability of the product. Our silicone coatings can be easily tailored to give your assets the added protection and insulation they need for extended service life. Team up with us to help your equipment get through the year with the least possible downtimes.

Download Technical Note

Please download the Technical note of the RTV Silicone High Voltage Insulator Coating.